In this article,

we will continue to introduce the key features with GN’s decanter centrifuge.

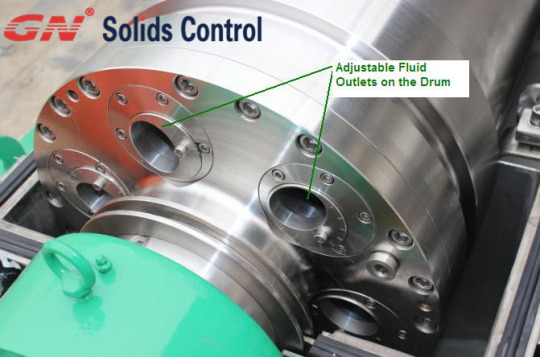

- Easily adjustable fluid outlet on the drum;

Sometimes

in order to change the drying degree of solids or clarity of liquid, the size

of fluid outlet on the drum needs to be changed by customer.

With

GN’s centrifuge, there are 6 fluid outlets at the big end of the drum and there

is a cover plate mounted on each outlet by bolts. It just needs to loosen the

bolts and angle the cover plate and the outlet size could be changed easily.

- Feeding fluid from the big end of centrifuge;

With

all GN’s centrifuges, the drilling fluid goes into the centrifuge from its big

end. Compared with feeding fluid from the small end of centrifuge, on some

extent it will improve the working efficiency by feeding fluid from the big end

of centrifuge.

- Parts from world-famous suppliers;

1.The

bearing is 1 of the most important parts for the centrifuge. With GN’s

centrifuge, all the bearings are world-famous brands like SKF (Switzerland

brand), NSK (Japan Brand), FAG (Germany Brand).

2.

All the electrical components used in the electric cabinet are also from famous

brands like SCHNEIDER (France Brand), SIEMENS (Germany Brand), CHINT (China

Brand), ABB(Switzerland Brand).

For

example, for the inverter of GN’s variable speed centrifuge, it is from ABB

Group.

By

adopting these high-quality parts, GN guarantees to provide the best centrifuge

with perfect work performance and longer life to all the customers from the

world.

- Explosion-proof property;

1.

Exd Standard;

2.

Positive Pressure Type;

Both

the motors and electric cabinet with GN’s centrifuge get through the IEC and

ATEX certification and could meet the explosion-proof requirement in developed

countries.

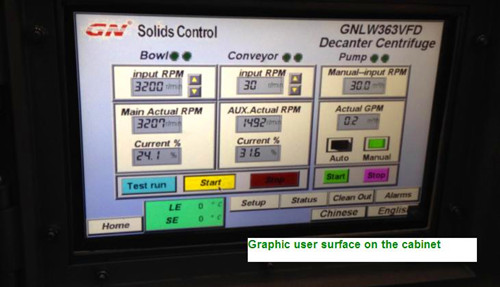

- PLC intelligent control

For

the electric cabinet of GN’s variable speed centrifuge, it has a graphic user

interface and is PLC intelligent control, which could achieve centrifuge’s

self-protection and guarantee its most effective work.