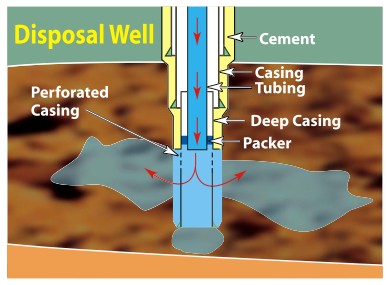

Drilling cuttings re-injection (CRI) is an in situ method for the disposal of drilling cuttings and other drilling wastes into a sub犀利士

-surface stratum.

Drilling cuttings are slurriified with waster and groud down to a pre-determined partical size. The partical size is achieved by passing through a shaker screen. Slurry of the correct particle size and physical properties is injected via a pump, which is typically of a triplex design, into the well head at a given pressure and down into the pre-determined sub-surface injection zone. Over size particals from the shale shaker are re-circulated for further grinding.