- Project introduction

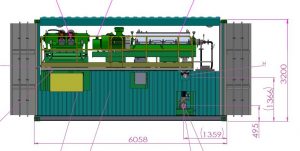

1.1Customer Project Plant Address:Sarangani Energy CorporationKamanga Agro Industrial Econominc Zone Brgy. Kamanga, Maasim, Sarangani Province, Philippines 9502

1.2 Customer requirements:

For Sludge concentration, image below shows 40 to 80 % moisture.

Particle size range of 500 to 800 microns (average) sludge of aluminum based coagulant

75% Calcium coagulation sludge and 25% lime softening sludge. Other use : sand silt (50% moisture),29degC for material and 32degC for Ambiet

2.GN solids/sludge vacuum pump Model GNSP-40B introduction.

2.1Brief introduction

Sludge vacuum pump, also named as solids transfer pump. It is a type of pneumatic pump that sucks the material with vacuum produced by air operation, and then converts to positive pressure for discharging.Most of the solids, sludge and liquid could be transferred by using this pump. With special structure design of no rotating parts in the cavity, it can be used at tough environmental with high working performance and less maintenance. The pump can transfer material with high gravity and high density, solids content max.up to 80%. It has following features: the high efficiency venturi device can produce vacuum up to 25 inch HG(Mercury Column). This is equivalent to vacuum of 85Kpa to suck the material. The pump structure is simple and compact, almost none of wear parts. The transfer distance is up to 500-1000 meters.

2.2 Advantages

Air operation, no need electric power, suitable for hazardous area application.

Powerful self-suction with long transfer distance. Suction distance up to 50 meters, discharge distance up to 500-1000meters.

Widely application for transferring liquid, wet sludge and solids.

Transferred solids size Maximum50 mm or 75 mm, sludge solids content up to 80%.

Compact structure for easy to move.

None of rotating parts inside the cavity, less wearing for long lifetime.

Automatically and continuously working is available with easy operation and maintenance.