GN Separation is excited to announce our participation in the 2024 China Mining Conference, one of the most influential events in the mining industry. The event will take place in Tianjin, China, and we warmly welcome you to visit us at Hall N2, Booth 2301A for business discussions and to explore how our innovative solutions can benefit your operations. For more information on the event, please visit the official website: China Mining Conference.

At this year’s conference, we will be showcasing our GN 2-Deck Stack Vibrating Screen, an advanced piece of equipment ideal for fine-grained material processing, including wet screening, classification, and dehydration treatment. The GN Stack Vibrating Screen has been widely used in industries such as mineral processing and coal preparation, thanks to its adaptability and high efficiency.

Why Choose GN Stack Vibrating Screen?

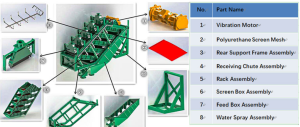

The GN Stack Vibrating Screen, developed in-house by GN Separation, is designed using the dual-vibration motor principle to achieve precise linear vibration. With the flexibility to configure 2 to 5 layers based on operational requirements, the screen provides energy savings, high screening efficiency, and a large processing capacity. Its simple, yet robust structure ensures stable and reliable performance, making it one of the most advanced screening systems in the market today.

Key Features:

- High Screening Efficiency: With an energy-saving design, GN Stack Vibrating Screen offers high performance for fine-grained material screening, providing excellent processing capacity with minimal power consumption.

- Polyurethane Screen Mesh: The screen features a high opening rate (28-45%) and an average lifespan of over 6 months, ensuring durability and reduced maintenance costs.

- Advanced Design: Our screens utilize a multi-layer structure with small footprints, making them suitable for operations where space is limited but processing efficiency is crucial.

- Durable and Reliable: The screen adopts advanced anti-corrosion treatments and is equipped with a modular feeding box that increases screen longevity, reduces damage, and lowers operational costs.

The GN Stack Vibrating Screen is customizable based on customer needs, making it suitable for a wide variety of materials and working conditions. Its modular design also ensures easy maintenance and cost-effective operation over the long term.

Technical Highlights:

We offer a range of small and medium to medium and large Stack Vibrating Screen models, allowing for optimal customization based on the requirements of your project. These models are available with various technical specifications such as:

- 2 to 5 screen layers

- A processing capacity of up to 42 m³/h (depending on the model)

- A mesh size range from 0.045 to 2mm

- Energy-efficient motors and flexible screen inclination

For a full overview of technical parameters, we encourage you to consult our team at the conference or contact us directly.

Visit Us for Tailored Solutions

Whether you’re looking for solutions in wet screening, classification, or fine material dehydration, GN Separation’s Stack Vibrating Screen is an excellent choice. We also offer other high-performance equipment that may meet your needs, so feel free to consult with us at the event.

We look forward to meeting you at Hall N2, Booth 2301A to discuss how we can help optimize your mining operations.