1.Project Description

1.1BoxLNG is an Indian Company focusing on developing Low Carbon Distributed Renewable Natural Gas (RNG) Production Plants across India. We are looking to procure Dewatering Machine (Solid Liquid Separator/ Filter Press) for a Multi-Feedstock Biogas plant for Prees Mud, Chicken Litter, Cattle Dung, Rice straw, Food & Vegetables MSW etc.,treatment and separation.

1.2 The origin and geographic location of the waste BIOGAS PLANT Organic Waste & Agriculture Waste including Cattle dung, press mud, chicken litter, Rice straw, Vegetable & food, Spent wash & MSW). the makeup of the waste,Water with Organic Waste Slurry.The maximum solids size or Particle Size.Maximum Size 20 – 10 mm.The challenge or problem of the current situation is challenging for Solid liquid Separator Maximum 50-60% of Solid Removal / (12 -15 % Solid) Form diagestate Tank.

The process and equipment is being used on location at present. And the performance now is Solid Liquid Separation Process and Solid Liquid Separator with Maximum 50-60% of Solid Removal

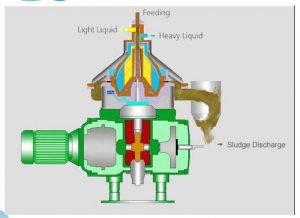

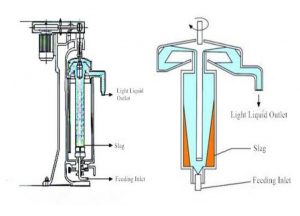

2. The GN two phase Decanter Centrifuge feature and advantage introduction.

2.1 Introduction of GN two phase Decanter Scroll Discharge Centrifuge:

The centrifuges made by our factory can clarify,dehydrale and classify the suspensiens with 0.002-3mm solid Phase particles. As structure features,the products two-phase classification. It

is suitable to separate various materials under different working conditions

2.2 Separation and dehydration of industrial and domestic sewages.Such as, Washing and dehydration of starch,Dehydration of soybean wheat proteins,Dehydration offish meal and fish,Dehydration of brewers’ grains, Purification of juice and dehydration of fruit fiber. Separation and punlication of animal and vegetable oil, Separation and purification of coal tar, Clarification and purification of gypsum, Classification and dehydration of starch, Classification and dehydration of Kaolin and graphic, Classification and dehydration of dyes and pigments, .Classification and dehydration of mineral thick liquid