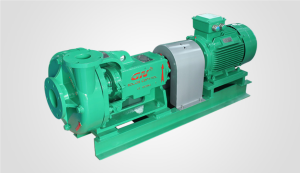

In the demanding world of industrial operations, efficient and reliable equipment is crucial. GN Separation is proud to offer the GNSB Series Centrifugal Mud Pump, designed to meet the rigorous needs of various industries. Whether you’re involved in drilling, construction, environmental waste management, or mining, the GNSB Series provides an optimal solution for transferring industry slurry and wastewater with solids less than 2mm.

Key Features and Specifications

The GNSB Series Centrifugal Mud Pump stands out for its durability and high performance. It’s engineered to handle high-volume, high-temperature slurries and can manage abrasive and high-viscosity fluids effectively. The pump’s rugged design is field-proven, ensuring reliability in demanding applications.

Here’s a snapshot of the GNSB Series specifications:

- GNSB8×6C-14J: 320 m³/h flow, 35m lift, 75 kW power, 1450 RPM (50Hz), 14-inch impeller

- GNSB8×6C-12J: 1750 RPM (60Hz), 12-inch impeller

- GNSB8×6C-13J: 272 m³/h flow, 35m lift, 55 kW power, 1450 RPM (50Hz), 13-inch impeller

- GNSB6×5C-13J: 200 m³/h flow, 35m lift, 45 kW power, 1450 RPM (50Hz), 13-inch impeller

- GNSB5×4C-13J: 120 m³/h flow, 35m lift, 30 kW power, 1450 RPM (50Hz), 13-inch impeller

- GNSB3×2C-9J: 35 m³/h flow, 35m lift, 7.5 kW power, 1450 RPM (50Hz), 9-inch impeller

All spare parts are interchangeable with NOV Mission Pump, ensuring easy maintenance and parts availability.

Advantages of the GNSB Centrifugal Mud Pump

- Standard Spare Parts: Facilitates straightforward maintenance.

- Durable Construction: Abrasion-resistant pump casing and impeller made from hard ductile iron alloy.

- Improved Bearing Life: Wide open-vane impeller design reduces axial thrust.

- Efficient Operation: Concentric design minimizes turbulence and abrasive wear.

- Secure Design: Anti-loosening impeller lock bolts prevent damage from incorrect running directions.

- Longer Operation Life: Tungsten carbide mechanical seals ensure zero leakage and extended service life.

- Replaceable Shaft Sleeve: Protects against complete shaft wear.

- Top-Brand Bearings: Utilizes reliable bearings from NSK, FAG, or SKF.

- Stable Support: Fully cast pump skid offers better stability compared to welded alternatives, improving the coupling and bearing life.

Applications Across Industries

The GNSB Series Centrifugal Mud Pump is versatile and widely used across various industries, including:

- Environmental Slurry Treatment: Efficiently handles environmental waste fluids.

- Wastewater Treatment: Ideal for transferring wastewater with solid content.

- Mining & Construction Mud Treatment: Suitable for managing mining slurry and construction mud.

- Chemical and Pharmaceutical Industries: Handles high-viscosity and abrasive fluids.

- Oil and Gas Industry: Transfers fluids in challenging oil and gas applications.

- Food and Beverage Industry: Used for specific slurry and waste fluid handling needs.

Conclusion

GN Separation’s GNSB Series Centrifugal Mud Pump is a robust and reliable solution designed to meet the needs of various industrial processes. Its advanced features and proven performance make it an excellent choice for handling demanding slurry and wastewater applications. For more information or to discuss how the GNSB Series can benefit your operations, please contact us.