1.Indonesia emulsion and resin projectbackground and introduction

The dryer would be dewatering mixed raw wastewater from 2 sources: emulsion and resin production which has a sticky character. The TS is high (around 10%) but it is still flowable.VTS is 98% and 82%, which means the wastewater does not have much inorganic content. Overload and sludge blocking did not happen at the pilot test. Flocs were formed and sludge cake was produced. The filtrate of the emulsion waste was pinky (dirty) We assume that this could be improved by polymer dosing adjustment.

Treatment capacity requirements by this project: 30 kg-DS/h for Waste activated sludge /Raw wastewater at TS 1%

2. GN sludge dewatering screw press model GNDL-301 features

2.1 Introduction of GN screw press sludge dewatering machine

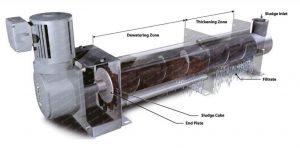

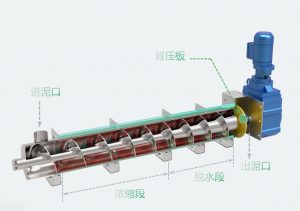

This is a kind of economic and environmental friendly sludge dewatering equipment. It is a new type of sludge extrusion dewatering equipment by using the principle of screw extrusion, through the strong squeezing force generated by the change of screw diameter and screw pitch, and the tiny gap between the floating ring and the fixed ring, to realize solid-liquid separation.

GN dewatering screw press is composed of fully automatic control cabinet, flocculation modulation box, sludge thickening and dewatering device, and liquid collecting tank. GN dewatering screw press is with automatic control technology, which can realize the flocculation fully automatic operation, and continuously complete the sludge thickening and squeezing, finally return or discharge the collected filtrate liquid.

GN screw press dewatering machine is widely used in sewage treatment projects of municipal, aquaculture, food, starch, oil, pharmaceutical, chemical, paper, leather and other industries

2.2 Features of GN screw press dewatering machine

Suitable for wide range sludge dewatering and can be used for oily sludge treatment.Operating continuously and automatically, not easy to block. Low investment and operation cost, no secondary pollution.Energy saving and environmental friendly, compact design with small footprint.Sludge can be dewatered under aerobic conditions to avoid phosphorus release from anaerobic sludge dewatering.