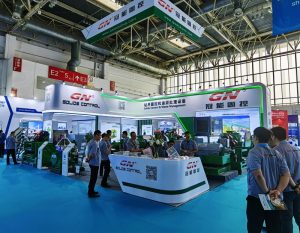

GN Solids Control glad to invite all of our clients and friends to attend the world largest Oil & Gas exhibition CIPPE in Beijing New China International Exhibition Center

- Exhibition Name: The 24th China International Petroleum & Petrochemical Technology and Equipment Exhibition(CIPPE 2024)

- Exhibition time: 25th-27th, March, 2024,

- GN Booth No.: E2168

- Offical website: https://en.cippe.com.cn/

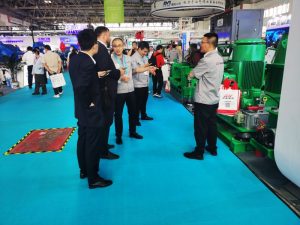

As the world famous brand solids control equipment manufacturer and drilling waste management equipment systems, GN Solids Control has been devoted to supplying the most cost-effective products in thousands of drilling rig sites. Without doubt, CIPPE (https://en.cippe.com.cn/) 2024 is a great show, we will be excited to meet clients at our booth.

GN will show the following equipments during the fair:

GN ViST shaker is a traditional shaker fixed with vacuum screen unit. ViST helps to recover more than 20~30% liquid from the drilling mud, which is a large volume waste reduction and new drilling mud investment after year’s accumulation.

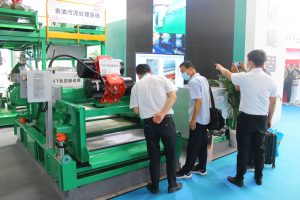

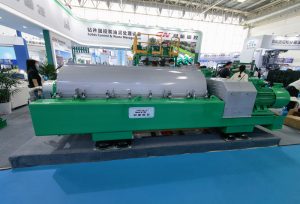

Decanter centrifuge is a core treating unit for the solids and liquid separation. GN will bring 2-phase decanter centrifuge GNLW632A, GNLW554FT-VFD, and 3-phase decanter centrifuge GNLWS364FT-VFD to the exhibition.

Disc stack separator is a device that rapidly separates solid and liquid through high-speed centrifugal force. GN will bring a 3-phase disc stack separator GNSD90 to the exhibition.

Cuttings Dryer is largely used for OBM and SBM treating, oil in the cuttings can be controlled less than 5% from above 15%. GN Solids Control provides cuttings dryer with different sizes of screen basket, which can be changed for different materials.

GN Solids Vacuum Pump is an ideal equipment for high-speed transferring sludge with high solid content up to 80% and high specific gravity material.

Screw conveyor is mainly used to remove drill cuttings discharged from shaker, desander, desilter. It is an effectively solids transfer unit within certain length.