Introduction: In recent times, GN Separation(GN) has received high praise for its advanced High Shear Circular Screens, particularly the GNYK1028 model. These screens have not only garnered international recognition but have also played a pivotal role in advancing overseas projects. This success signifies not only the growing trust of global clients in GN’s High Shear Circular Screens but also a positive feedback loop from the worldwide market, acknowledging GN’s 15 years of expertise in the separation and conveying industry.

Working Principle of GNYK1028 Circular Motion Screen:

The circular motion screen features a single-layer, multi-stage arrangement driven by a single excitation source, typically a vibration motor. This motor generates an inertia force following a sinusoidal pattern around the central axis, resulting in circular motion of the entire screen assembly. This motion is then transferred to the screen mesh, achieving the desired vibration separation of materials.

Workflow of GNYK1028 High Shear Circular Screen:

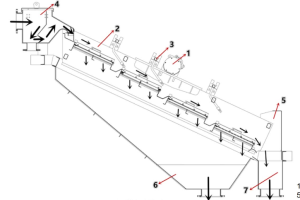

- The material is fed from the superior feeding equipment, passing through the buffering and material distribution in the feeding box assembly (4).

- The vibration motor (1) generates vibrations, driving the circular motion of the screen box assembly (2). The material moves from the rear end to the front end of the screen box assembly. In the middle of this process, water is sprayed through the water spray assembly (3) to re-suspend and re-slurry the material, facilitating better classification.

- During the motion, material smaller than the openings in the screen mesh eventually falls into the collection trough assembly (6) under the screen, while material larger than the screen mesh openings is blocked by the discharge baffle (5) and eventually falls into the collection trough assembly (7) above the screen. The separated materials from above and below the screen enter the next processing step separately.

Applications in Various Industries:

Construction Materials Industry: GN’s High Shear Circular Screens are widely used in the screening and classification of raw materials like sand and cement. The efficient vibration source and multi-stage design ensure even distribution, enhancing production efficiency in the construction materials industry.

Mining Industry: In mining, GN circular motion screens find applications in the screening and grading of ores. Corrosion-resistant design and adjustable angles make them suitable for various types of ores, improving grade and purity.

Chemical Industry: In chemical production, GN circular motion screens are employed for screening materials such as fertilizers, plastic particles, and rubber. The flexible polyurethane screen mesh and adjustable angles ensure precise and efficient screening, meeting industry standards.

Metallurgical Industry: GN circular motion screens are extensively used in the metallurgical industry for screening metal powders and iron ores. The high-temperature resistance and wear-resistant design make them adaptable to the demanding conditions of metallurgical processes.

Environmental Sector: In solid waste and cement processing for environmental purposes, GN circular motion screens play a crucial role. Accurate screening separates recyclable materials from waste, offering a viable solution for environmental industries.

Key Features of GN High Shear Circular Screens:

The screen utilizes a single vibration motor as the vibration source, enabling the circular motion of the entire screen assembly. The motor is sourced from reputable brands such as Martin or OLI, known for their reliable performance and extended trouble-free operation.

The screen assembly is designed with multiple sections, providing significant advantages such as high processing capacity, efficient screening, low power consumption, minimal dynamic loads, simple operation, stable performance, durability, and reduced maintenance requirements. This design ensures both optimal efficiency during operation and decreased costs and time associated with routine maintenance.

The adjustable angles of the screen assembly facilitate convenient and reliable operation. Additionally, the incorporation of a water spray system between each screen section enhances material classification, ensuring superior screening effectiveness.

The screen assembly undergoes comprehensive heat treatment, ensuring its ability to withstand prolonged operation under high vibration intensity.

Electrical components are sourced from internationally renowned brands such as Siemens or Schneider, ensuring stability and reducing the difficulty of overseas customer self-maintenance.

The screen mesh, one of the most vulnerable components in vibrating screens, is made of flexible polyurethane. This material provides excellent elasticity, preventing clogging, allowing the installation of four to five layers of mesh, and maintaining low equipment noise during vibration.

The screen mesh is secured using bolted components, ensuring easy operation, reliable fastening, and facilitating convenient inspection, disassembly, and installation of the screen.

Emphasizing both corrosion resistance and aesthetics, GN employs sandblasting for the surface treatment of the high shear vibrating screen. It is coated with heavy-duty anti-corrosion paint, exhibiting excellent corrosion resistance. The contact surface with materials is coated with wear-resistant polyurethane resin or affixed with wear-resistant rubber sheets, effectively protecting the screen machine surface and extending its operational lifespan.

At the end:

The successful application of GN’s High Shear Circular Screen has injected a new vitality into overseas silicon sand grading projects, elevating the quality and output of silicon sand. GN’s continuous efforts in technological innovation and enhancing equipment performance and stability for the High Shear Circular Screen have gained recognition from clients in both domestic and international silicon sand processing industries. GN is committed to ongoing innovation, providing efficient and reliable High Shear Circular Screening solutions for global customers.