All mud agitators and mud conditioners share the same simple design and rugged components. With minimal replacement parts, they provide years of dependable, economical service. Smaller solids that may bypass the agitators can be removed by Brandt hydrocyclones. Brandt mud conditioners save valuable fluid by drying the hydrocyclone underflow with efficient linear motion.

Gnsolidsamerica.com mud agitator are ideal for“closed-loop” operations or whenever excessive liquid loss from hydrocyclone underflows must be avoided. When liquid loss is not a concern, the hydrocyclone underflow may be directed away from the screens by simply opening the bypass valve. This minimizes liquid pools and reduces undue weight on screens.

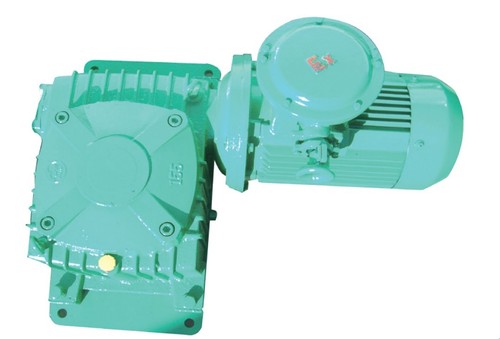

The causes of damage of mud agitator are: 1. The drilling fluid density, high viscosity, mixer, low power, overload use 2. Don’t insist on continuous operation, drilling fluid static for a long time after the start, by overload 3. Can’t adhere to timely maintenance moist 4. Installation is unreasonable, no cover or fan operation 5. Fixed condition is bad, screw loosening, or a fixed screw is not complete, large vibration and damage, these can cause damage to the blender. Mud agitator in order to adapt to the need of more comprehensive drilling, it is the trend of future: timing, constant speed, single, such as choosing a variety of functions, easy operation, stable starting torque, rotational speed, low noise, etc. GN solids control company staff to build professional e-commerce website, here, we will show you the best mud mixers, as well as our online services platform to answer your problem. If you want to get it, click here to go directly to the page, I believe your choice, can’t be wrong.